Short Lead Time for Dry Core Drill - Surface Conditioning Discs Quick Change Metal Sanding Discs – Tranrich

Short Lead Time for Dry Core Drill - Surface Conditioning Discs Quick Change Metal Sanding Discs – Tranrich Detail:

The Feature of Surface Conditioning Discs:

High Performance for Various Work: The quick change sanding discs fits various surface conditioning and preconditioning situation: paint, rust, glue or adhesive removal, self-sharpening, sanding, cleaning, grinding, stripping, deburring, polishing, finishing, etc.

Quick-change & Steady Design: With a unique safety torque spiral, the connection between the sanding disc and the holder/tray gets firmly when rotating, ensuring a steady working and no fallout. Roll lock quick-change design just twists it to remove or connect.

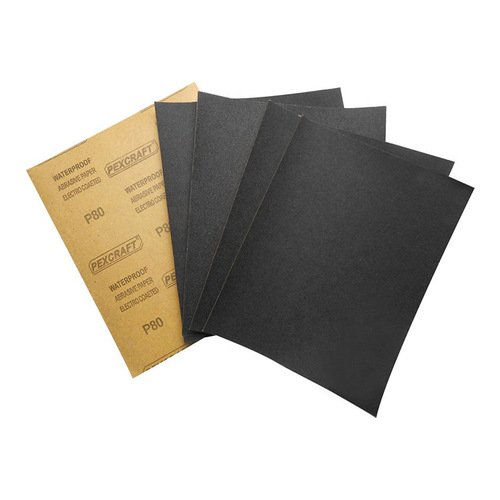

Perfect for All Surface: Quick change sanding disc based on special fiber as substrate with abrasive particles Silicon Carbide pasted, get an open-mesh 3D structure, better elastic and plasticity, suitable for different shapes of various objects, works well even on rugged surface. Quick heat dissipation to avoid overheating deformation or discoloration. 2 inch sanding disc is perfect for detail work on tighter contoured areas and it provides sufficient coverage area to handle larger surfaces, plays well on all surfaces

Long-term Sharp: Silicon Carbide with high hardness and brittleness, irregular fracture and collapse broken happens when grinding, keep producing new edges and corners to keep sharp. So sanding disc keeps strong cutting force and high performance for quite a long time. It is a piece of cake to handle hard and brittle materials, such as cast iron and cemented carbide.

Extensive Use: Sanding discs are suitable for stainless steel, alloys, iron, non-ferrous materials. Polishing like shipbuilding, repairer, aviation, machinery. Metal processing like automotive, motorcycle sheet metal coating, metal stamping, die casting parts, instrumentation, bicycle parts, textile machinery, medical equipment parts, tools, knives, pen parts, Hardware, plumbing equipment, golf head, electric vacuum products such as surface finishing, deburring, round and mirror polishing.

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for Short Lead Time for Dry Core Drill - Surface Conditioning Discs Quick Change Metal Sanding Discs – Tranrich , The product will supply to all over the world, such as: Wellington, Moldova, Russia, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.